All-in-one Factory for everyone

ElitePipe Factory

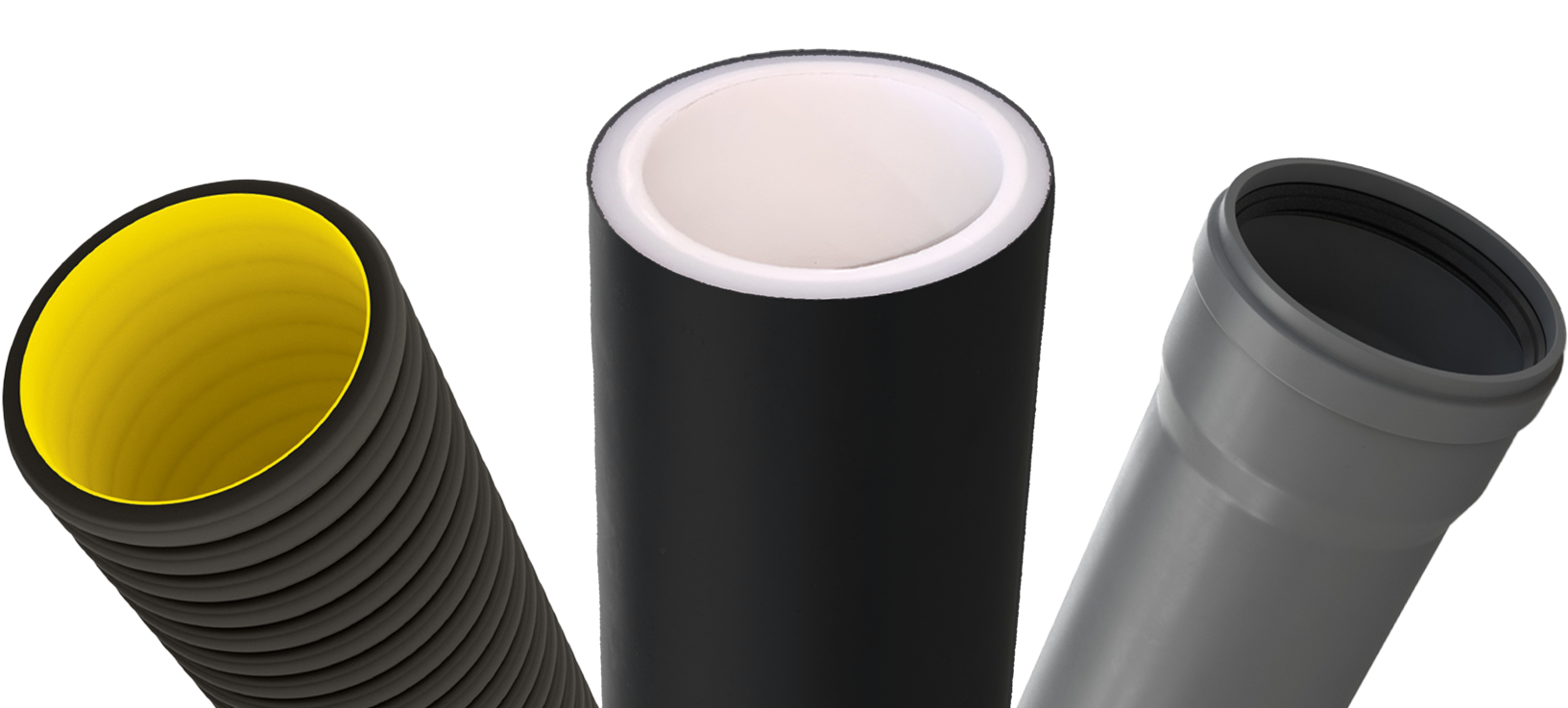

Our plastic factory produces a range of high-quality plastic products to meet different needs and applications. One of our primary products is the high-density polyethylene (HDPE) pipes used in water supply, gas, and plumbing systems. We also produce unplasticized polyvinyl chloride (uPVC) for construction purposes, including doors, windows, pipes, and fittings. Additionally, our factory produces strong, durable fiberglass or Glass Reinforced Plastic (GRP), which is widely used in commercial and industrial applications, such as tanks, water pipes, and electrical components. Our selection of fittings, including couplings, valves, and elbows, allows for easy connection of pipes and changes in direction or size. Lastly, we also offer high-quality irrigation pipes designed for horticulture and agricultural applications. We take pride in our products and ensure they meet our stringent quality control standards.

Why Elitepipe Plastic Factory?

The future of the industry

Elitepipe Plastic Factory is a leading manufacturer of high-quality plastic pipes and fittings in iraq. we offer a wide range of products, including HDPE, UPVC, and GRP pipes and fittings, that are suitable for a variety of applications in different industries, such as water supply, drainage, sewage, and irrigation.

Features

Elitepipeiraq offers a variety of features to enhance their customer’s experience. First, we provide high-quality pipes that are durable and long-lasting. These pipes are made from high-quality materials that are resistant to corrosion, making them ideal for a range of applications , Elitepipeiraq also offers a customization service that allows customers to modify their pipes to suit their specific needs.

Hdpe Pipes

HDPE (High-density polyethylene) pipe is made of a thermoplastic material that is renowned for its durability, strength and flexible properties. PE100 is a high quality, high-density polyethylene material that is used to manufacture high pressure pipes. It provides exceptional long-term strength and durability, resistance to chemicals and environmental elements, and has a high level of impact resistance.

HDPE pipes made of PE100 material are widely used in various industries such as water distribution, gas transmission, sewage systems, irrigation, and industrial applications. They are preferred due to their high performance, low maintenance and long service life. Furthermore, HDPE pipes are easy to install, corrosion resistant, and leak-free.

HDPE pipes made of PE100 material comply with the standards set by international organizations such as ISO, DIN, EN, and ASTM. These standards ensure that the pipes are of the highest quality and meet the required specifications.

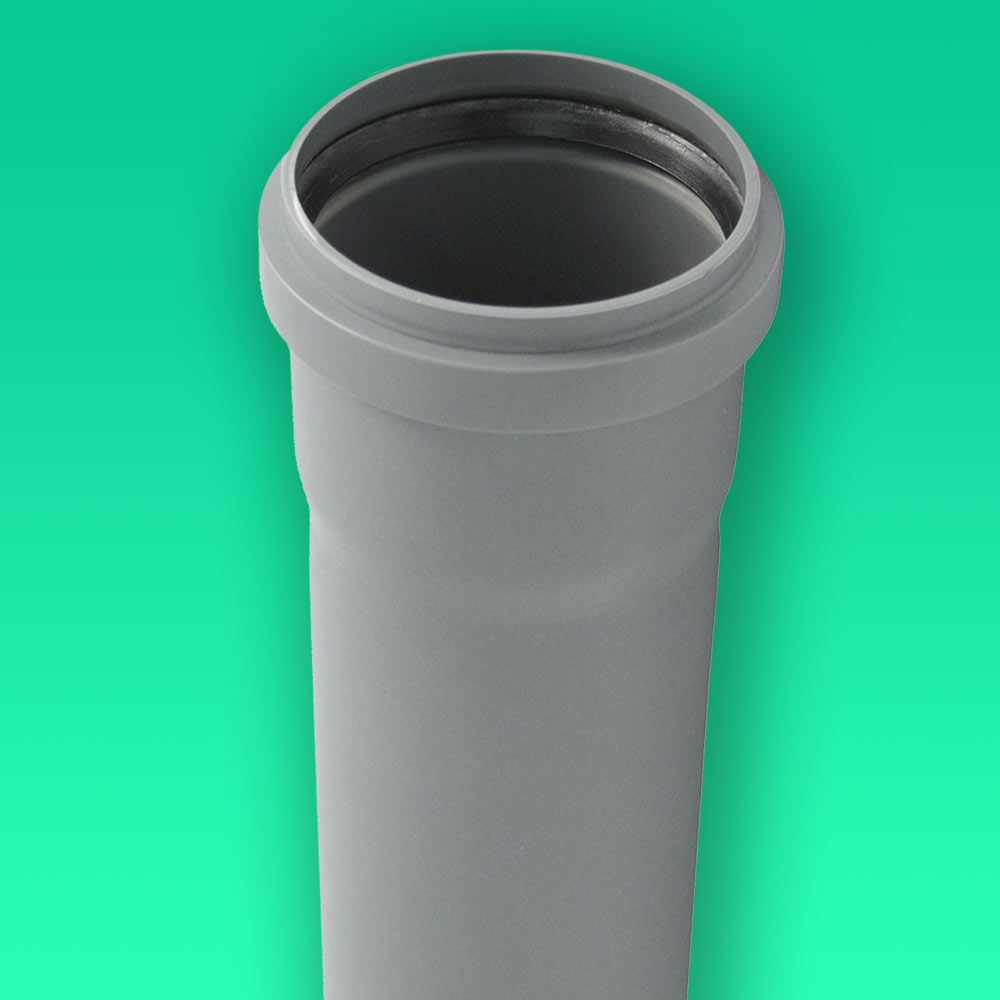

Upvc Pipes

UPVC pipe is a type of plastic pipe made from polyvinyl chloride (PVC) resin, which is committed to being environmentally friendly and safe for human health. It is widely used in plumbing, drainage, and irrigation systems due to its high quality and durability. UPVC pipes are non-corrosive and resistant to chemical and physical degradation caused by extreme weather conditions, making them ideal for outdoor applications. Additionally, they are lightweight and easy to install, resulting in significant cost savings compared to traditional piping materials. UPVC pipes meet international standards for quality and safety, ensuring that they are safe and reliable in use. In summary, UPVC pipes are a high-quality, cost-effective, and safe solution for a wide range of piping applications.

Grp Pipes

GRP pipes, also known as Glass Reinforced Plastic pipes, are thermosetting plastic pipes that are reinforced with fine glass fibers. They are commonly used in a variety of industries including oil and gas, chemical, water and wastewater treatment, and marine. GRP pipes offer a number of advantages over other types of pipes, including their durability, corrosion resistance, and light weight. They are also highly resistant to extreme temperatures and are able to withstand high pressure and stress. In addition, GRP pipes are easy to install and maintain, which makes them a popular choice for many industrial applications. Overall, GRP pipes are a reliable and cost-effective solution for a wide range of piping needs.

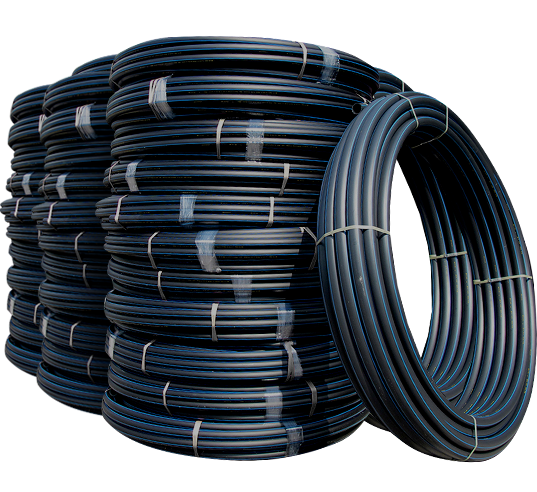

LDPE Pipes

LDPE pipes, also known as low-density polyethylene pipes, are highly regarded in the water and gas distribution industry due to their advantageous properties, including excellent flexibility, durability, and corrosion resistance. Nevertheless, the quality of LDPE pipes is variable, thus making the selection process a crucial one, tailored to your specific requirements.

The quality of LDPE pipes hinges on reliable suppliers who use only the highest quality and most robust materials that comply with stringent manufacturing standards. Equally important is the selection of LDPE pipes with proper specifications for your intended application, which includes size, wall thickness, and pressure rating.

Moreover, consistent testing, inspection, and maintenance routines will warrant that LDPE pipes perform at top-notch standards. These protocols encompass leak testing, pressure loss evaluation, and identification and handling of other possible issues.

Conclusively, investing in prime LDPE pipes will contribute to enhancing the reliability and long-term performance, while reducing risks, such as loss of productivity and significant expenses, that result from leaks and unexpected outages.

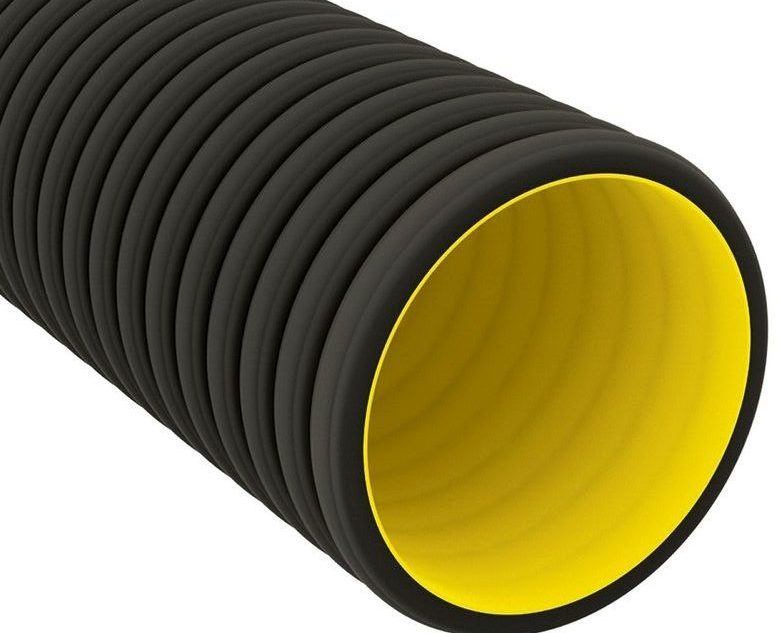

Corrugated Pipe

Corrugated pipe is a type of piping that features parallel ridges that run along its length. It is widely used in various construction and engineering applications, particularly in the drainage and sewage industries. The corrugated design significantly increases the structural strength of the pipe, allowing it to withstand heavy loads and pressures. It is also flexible, allowing it to bend and adapt to different terrains and soil conditions. Corrugated pipe can be made of different materials, such as PVC, HDPE, and metal, and can come in various diameters and lengths depending on the intended use. It is an affordable and practical solution for managing and transporting water, sewage, and other fluids in residential, commercial, and industrial settings.

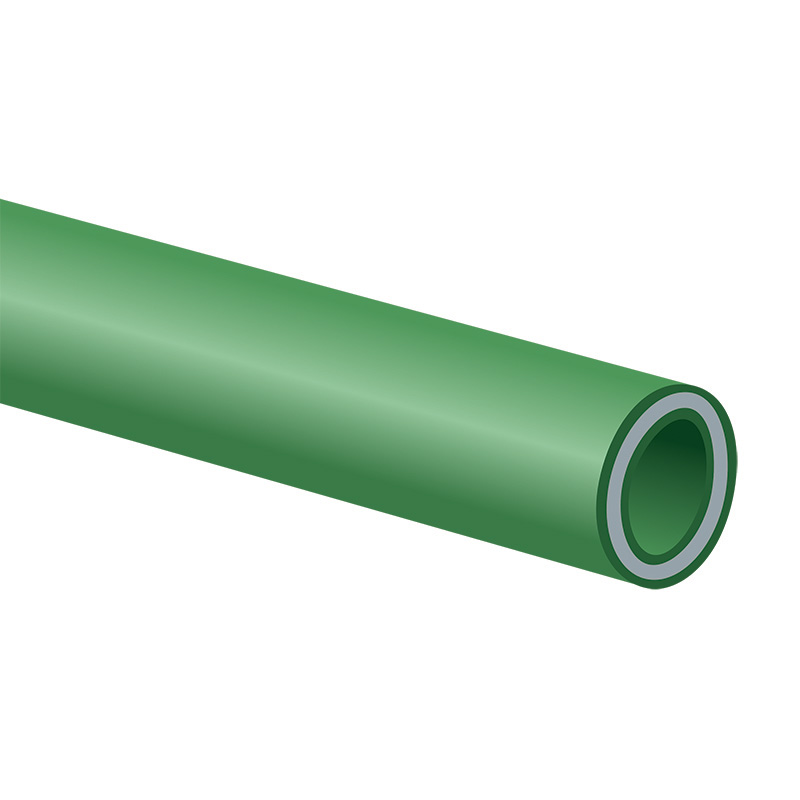

PPRC pipe

PPRC (Polypropylene Random Copolymer) pipes are a type of plastic pipes commonly used for transporting both hot and cold water in residential, commercial and industrial settings. They are made of thermoplastic material which is resistant to high temperature, chemical corrosion, and UV radiation which makes them durable and long lasting. PPRC pipes have a smooth surface that prevents the build-up of mineral deposits and rust, which can affect the quality of the water. They are easy to install and maintain, and their flexibility makes them ideal for use in areas with extreme temperature variations. Additionally, they are non-toxic and environmentally friendly, which is a benefit to both the environment and the user’s health. PPRC pipes are a cost-effective alternative to other traditional plumbing materials and are perfect for installing in new construction projects, renovations and repairs.

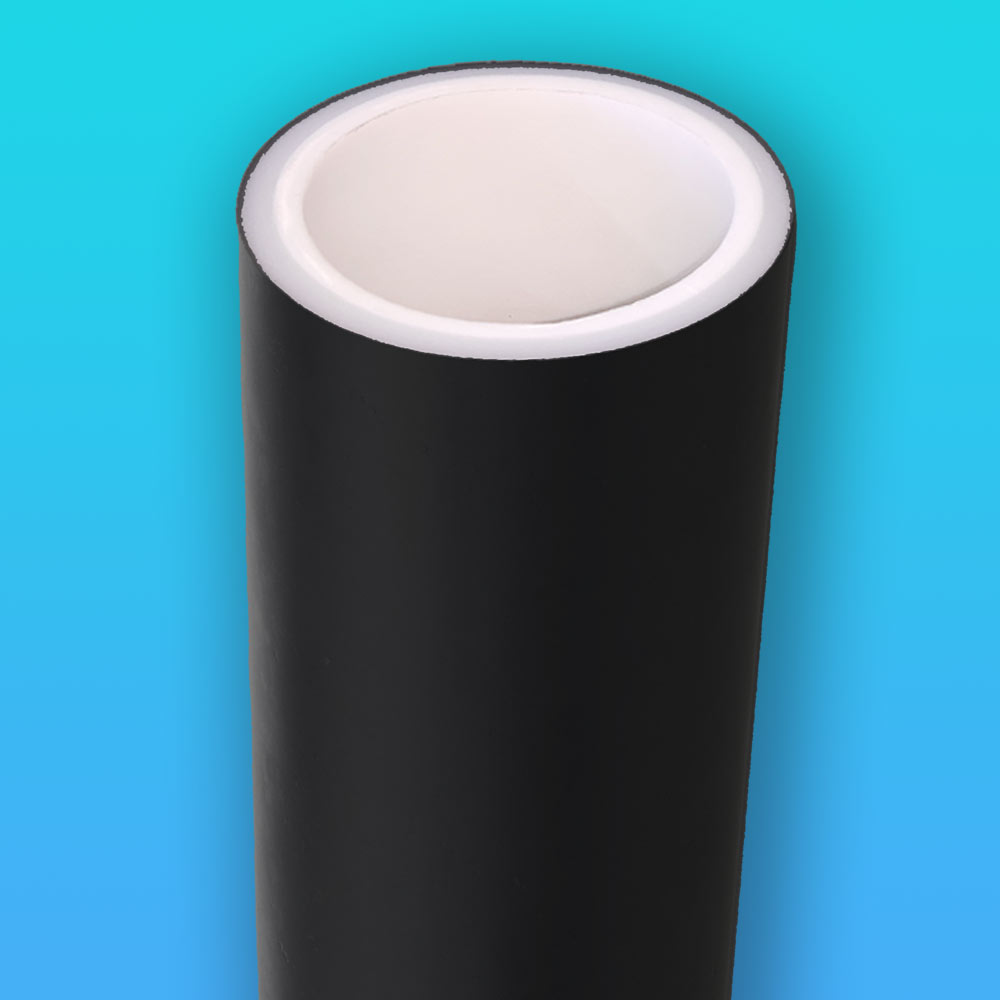

Hdpe Cable Casing

HDPE cable casing refers to the use of high-density polyethylene (HDPE) plastic in the construction of underground cable protective casings. These casings serve to protect electrical cables or fiber optic cables from damage caused by external factors such as impact, corrosion, water, and soil movement. HDPE cable casings are highly resistant to weather, chemicals, and moisture and can withstand a wide range of temperatures making them suitable for underground installations. They have a longer lifespan than traditional steel or concrete casings, require less maintenance, and are more cost-effective. HDPE cable casing is also more environmentally friendly as it does not release harmful chemicals into the surrounding soil like other materials. Overall, HDPE cable casings are a reliable and efficient method of cable protection that is increasingly popular in modern underground installations.

HDPE Electrofusion fittings

HDPE Electrofusion fittings are a type of piping accessory that are used to connect high-density polyethylene (HDPE) pipes. Electrofusion fittings use electric currents to heat up and melt the ends of the HDPE pipes, then fuse them together. This creates a strong, permanent bond between the pipes without the need for additional connectors or adhesives.

HDPE Electrofusion fittings are commonly used in water and gas pipelines, as well as in industrial and agricultural applications. Unlike traditional joining methods, such as butt fusion or mechanical connections, electrofusion fittings offer a seamless and highly efficient connection process.

Some benefits of HDPE Electrofusion fittings include their high durability, resistance to corrosion and abrasion, and ease of installation. They are also typically more cost-effective than other joining methods, due to their speed and efficiency.

Hdpe Coupling Fittings

HDPE coupling fittings are used in the joining of high-density polyethylene pipes, commonly used in water and gas distribution systems. The coupling fittings are designed with a threaded or grooved socket and a central stop to locate and align the pipes. With the use of heat fusion welding, the end of the pipe is inserted into the socket of the fitting, and when heated, the material melts and fuses together to form a strong, leak-proof joint. HDPE coupling fittings are available in various sizes, and their flexibility and resistance to corrosion, chemicals, and abrasion make them suitable for use even in harsh environments. They are easy to install, require no special tools, and offer a cost-effective solution to pipe connections, making them a popular choice for both commercial and residential plumbing systems.

Welding Machines of Plastic Pipes

Welding machines for plastic pipes are tools used to join two or more pieces of plastic pipe together through a process called welding. These machines use heat to melt the plastic and then fuse the pieces of pipe together. The resulting joint is strong and durable, capable of withstanding high pressures and constant use. Some common types of welding machines include butt fusion, electrofusion, and extrusion welding machines. Butt fusion machines are used to join two pieces of pipe by heating the ends and then pressing them together. Electrofusion machines use electrical current to heat a metal wire placed between the two pieces of pipe, creating a strong bond. Extrusion welding machines use heat to melt the plastic as it is fed through the machine, allowing for the creation of custom shapes and designs. Welding machines for plastic pipes are essential tools in industries such as plumbing, infrastructure, and construction.

Have any questions?

Please complete the form below and we will get right back to you.